ICF construction delivers superior storm resistance, fire protection, and long-term durability, especially in hurricane-prone, humid regions like Southwest Florida. SIPs perform well in colder climates where speed and airtightness are key.

SIP vs ICF: The Smarter Pick Depends on Where You’re Building

Choosing between SIP and ICF comes down to climate and priorities. SIPs suit colder zones and tight timelines with efficient insulation and fast builds.

ICFs are ideal for hot, storm-prone areas, offering unmatched strength, moisture resistance, and long-term durability with minimal upkeep.:

- SIPs = Fast builds, tight envelopes, colder zones

- ICFs = Long-term durability, storm resistance, hot/humid climates

- SIPs need precision; ICFs need planning but offer more resilience

- SIPs save time up front; ICFs save costs long-term

You’ll get the essentials right here, but if you’re building in a high-risk climate, the full breakdown ahead is worth reading. It might just change how you define a better-built home.

Understanding SIP and ICF: The Building Blocks Behind the Buzz

As energy codes tighten and more homeowners build for longevity, two wall systems are leading the conversation: Structural Insulated Panels (SIPs) and Insulated Concrete Forms (ICFs).

Both aim to outperform traditional framing in strength, efficiency, and comfort, just in very different ways.

What is SIP (Structural Insulated Panel) Construction?

SIPs are large prefabricated panels made by sandwiching a foam core between two structural boards, usually OSB.

These panels serve as both structure and insulation, going up quickly like puzzle pieces. With high R-values and tight seals, SIPs are ideal for cold climates and fast builds.

SIPs focus on speed and thermal performance, but require precise planning and protection from moisture.

What is ICF (Insulated Concrete Form) Construction?

ICFs use foam blocks stacked like giant Lego bricks, then filled with concrete.

The forms stay in place, offering insulation and structure in one. ICFs thrive in high-heat, high-moisture, and hurricane-prone areas due to their strength, fire resistance, and thermal mass.

Think of ICF as a steel-reinforced bunker wrapped in foam, quiet, solid, and built to last.

Where Are SIPs and ICFs Used in Real Homes?

Both systems are used in exterior walls, but beyond that, they play different roles.

SIPs often go into roofs thanks to their lightweight span capabilities, while ICFs are frequently used in foundations and full wall systems from slab to roof.

Some homes even combine the two, but most lean into one system depending on climate, design, and performance needs, which we’ll break down next.

Both systems offer major advantages, but the right choice comes down to how they perform where it counts.

Let’s break them down side by side so you can see which fits your build best.

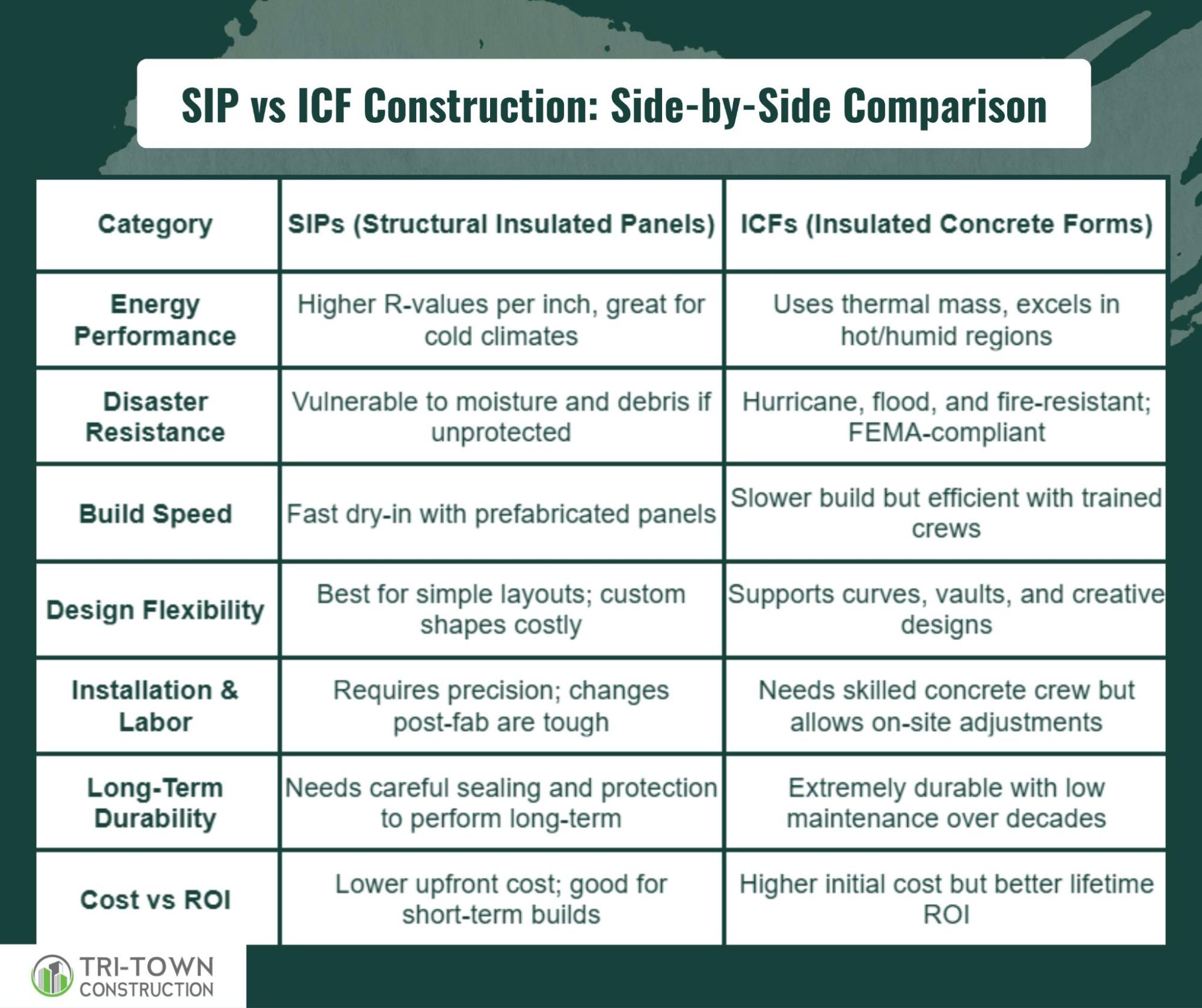

SIP vs ICF Construction: Comparing Them Side by Side

When it comes to choosing between SIP and ICF construction, it’s not always about which system is “better.”

The right choice depends on where you’re building, how you’re designing, and what performance outcomes matter most.

Below, we’ve broken down how each system performs across the key categories that matter in real-world homebuilding.

1. Energy Efficiency Beyond the R-Value

Efficiency is a big driver in choosing modern wall systems. SIPs and ICFs both offer advantages, but in very different ways.

SIP: SIPs offer higher R-values per inch, sometimes reaching R-40, providing excellent insulation in a thin profile. Their tight envelope reduces air leakage, ideal for cold climates where heat retention is key.

ICF: ICFs rely on thermal mass. The concrete core absorbs and slowly releases heat, reducing interior temperature swings in hot, humid climates.

When it makes sense: SIPs are best for cold zones. ICF wins in hot, moisture-heavy areas.

2. Disaster Resilience That Actually Holds Up

If you’re building in a region with hurricanes, floods, or wildfires, durability isn’t optional, it’s survival.

SIP: SIPs are structurally strong but more vulnerable to flying debris. Moisture or fire exposure can degrade the OSB layers unless additional protection is used.

ICF: ICFs are reinforced concrete cores inside foam, capable of withstanding 200+ mph winds and fire. They’re FEMA flood-zone compliant and field-tested in storm events.

When it makes sense: ICF is the clear choice in high-risk zones. SIPs are more suited for calmer climates.

3. Build Speed and Labor Simplicity

Time and labor impact everything from budget to weather exposure. This is where speed can make a difference.

SIP: SIPs are prefabricated and pre-cut, allowing quick on-site assembly. Dry-in can happen in days with a small crew.

ICF: ICF builds take longer due to stacking, bracing, and concrete pours, but trained crews can still move efficiently.

When it makes sense: SIPs are great for projects with tight deadlines. ICFs make sense when long-term durability outweighs speed.

4. Design Flexibility for Custom Homes

Not every home is a rectangle. The ability to adapt to curves, vaults, and creative architecture sets systems apart.

SIP: SIPs work well for straight walls and simple rooflines. Curves and late-stage design changes add cost and complexity.

ICF: ICFs can be cut and shaped on-site to accommodate unique designs. Curved walls, arches, and safe rooms are all possible.

When it makes sense: ICF is the pick for full design freedom. SIPs are better when the layout is planned and straightforward.

5. Installation Complexity and Skill Demand

No system installs itself, and ease of assembly can impact timelines, labor, and build quality.

SIP: SIPs are relatively simple but rigid. Precision matters, especially with air sealing, and changes post-fabrication are difficult and expensive.

ICF: ICFs require concrete skills and more setup, but offer flexibility on-site. Openings and details can often be adjusted mid-build.

When it makes sense: Choose SIPs when plans are locked and crews are ready. Pick ICF when adaptability and build control matter more.

6. Mechanical, Electrical & Plumbing Integration

Routing utilities through walls isn’t always straightforward. Some systems offer more flexibility than others once the walls are closed up.

- SIP: SIPs come with built-in chases, but once sealed, changes or additions are hard and expensive.

- ICF: With ICFs, installers can cut channels in the foam as needed, offering more field flexibility, especially for future upgrades.

- When it makes sense: Choose ICF when long-term access and adaptability matter. SIPs are best when utility paths are locked in early.

Helpful Resource → Top Benefits of ICF Construction for Modern Homes

7. Fire & Mold Resistance Where It Matters

Building in humid or fire-prone areas requires materials that won’t break down over time.

- SIP: The OSB skin on SIPs can mold or delaminate if moisture gets in. Fire performance varies unless extra protections are added.

- ICF: ICFs are naturally mold-resistant and offer up to 4-hour fire ratings due to their concrete core and foam layers.

- When it makes sense: ICF wins in areas with moisture or wildfire risks. SIPs need extra care to stay protected long-term.

8. Soundproofing and Indoor Comfort

A home’s comfort includes sound control, especially in multi-story or high-noise areas.

- SIP: SIPs reduce some noise compared to stick framing, but panel seams can transmit sound if not sealed carefully.

- ICF: Solid concrete and foam layers in ICFs dramatically reduce both airborne and structure-borne noise.

- When it makes sense: ICF is better for quiet, peaceful interiors. SIPs may be fine in single-story or quieter environments.

9. Cost and Return on Investment

Initial budget vs. long-term savings, this trade-off matters in any build.

- SIP: Lower upfront costs and faster builds make SIPs more budget-friendly. Energy savings depend on climate and design.

- ICF: More expensive to start, but long-lasting durability and energy performance lower costs over time.

- When it makes sense: Choose SIPs for short-term or budget builds. ICF pays off in the long run, especially for forever homes.

10. Space Efficiency and Wall Thickness

Wall thickness impacts usable square footage and layout flexibility.

- SIP: Thinner walls leave more room inside, which can make a big difference on small or narrow lots.

- ICF: Thicker walls take up more space, but deliver better insulation and strength.

- When it makes sense: Go with SIPs when interior space is tight. ICFs make sense when performance outweighs a few inches of floor area.

While both systems have clear strengths depending on your build, no choice is perfect.

To make a fully informed decision, it’s just as important to understand where each system falls short.

What Are the Drawbacks? The Truth About SIP and ICF Downsides

Every building system has trade-offs, and knowing them upfront helps you plan smarter. Here’s a look at where SIP and ICF construction can fall short, depending on your design, budget, and location.

SIP Construction Drawbacks

SIPs work best when the project is tightly designed and installed with care. But in real-world builds, especially in humid or hurricane-prone areas, there are a few weak spots to consider.

- Moisture matters: If not perfectly sealed, SIPs can trap water, leading to mold or rot in humid climates.

- OSB faces wear over time: Especially in coastal zones, delamination and decay can shorten lifespan.

- Design changes are expensive: Curves, custom details, and last-minute revisions don’t come easy.

- Harder to update later: Running new wires or plumbing after install can damage panel integrity.

- Fire safety concerns exist: Some foam cores burn quickly, and fire departments may approach with caution.

SIPs can deliver energy savings and speed, but they leave little room for error. Builders must be detail-oriented and proactive with moisture control and fire-rated detailing.

ICF Construction Drawbacks

ICFs offer long-term strength and resilience, but they come with a few early considerations. Most are planning-related, not deal-breakers, especially if you’re thinking long-term.

- Upfront costs run higher: Materials and labor may cost more at the start, but long-term savings in energy and insurance often offset this.

- Wall thickness eats space: ICF walls are thicker, but the comfort, noise control, and insulation you gain are usually worth the trade.

- Skilled labor is a must: Concrete work benefits from experience, but many crews today are trained in ICF techniques or can learn quickly.

- Interior finish work needs planning: Fastening shelves or cabinetry takes forethought, but internal ties are designed to handle it.

- Takes longer to go vertical: ICFs aren’t the fastest system to dry in, but the added time pays off in durability and peace of mind.

ICFs may ask more up front, but what they return, low maintenance, strong performance, and long-term comfort, makes them a smart choice for serious homeowners.

So, SIP or ICF? Here’s When Each One Makes Sense

There’s no one-size-fits-all answer.

The right system depends on your location, project goals, and how long you plan to stay in the home. Here’s how to decide which one fits your build best.

When SIPs Make Sense:

SIPs are a smart choice when speed, simplicity, and budget are top priorities.

- You’re building in a cold or mild climate where airtight insulation matters

- You need a quick dry-in to meet tight construction timelines

- Your floorplan is straightforward and panel-friendly

- Local labor is limited and you need a system that installs efficiently

When ICF Makes Sense:

ICF is ideal for long-term builds in challenging environments.

- You’re building in a hurricane-prone or flood-risk zone like Southwest Florida

- You want a durable home with fire, mold, and storm resistance

- You care about quiet interiors and thermal comfort

- Your design includes curves, vaults, or a safe room

- You’re investing in long-term savings and peace of mind

Final Verdict: SIPs are effective when well-planned, but ICF offers a level of strength and resilience few systems match.

If you’re exploring ICF construction, Tri-Town can help you build smarter, stronger, and storm-ready, right from the foundation up.