Modular Home Timeline: What to Expect from Start to Finish

Modular homes are completed faster than traditional homes because of their streamlined, factory-based construction process.

In Florida, you can expect a full build, from permits to move-in, to take between 4 and 6 months on average. Smart planning and timing help keep the process efficient.

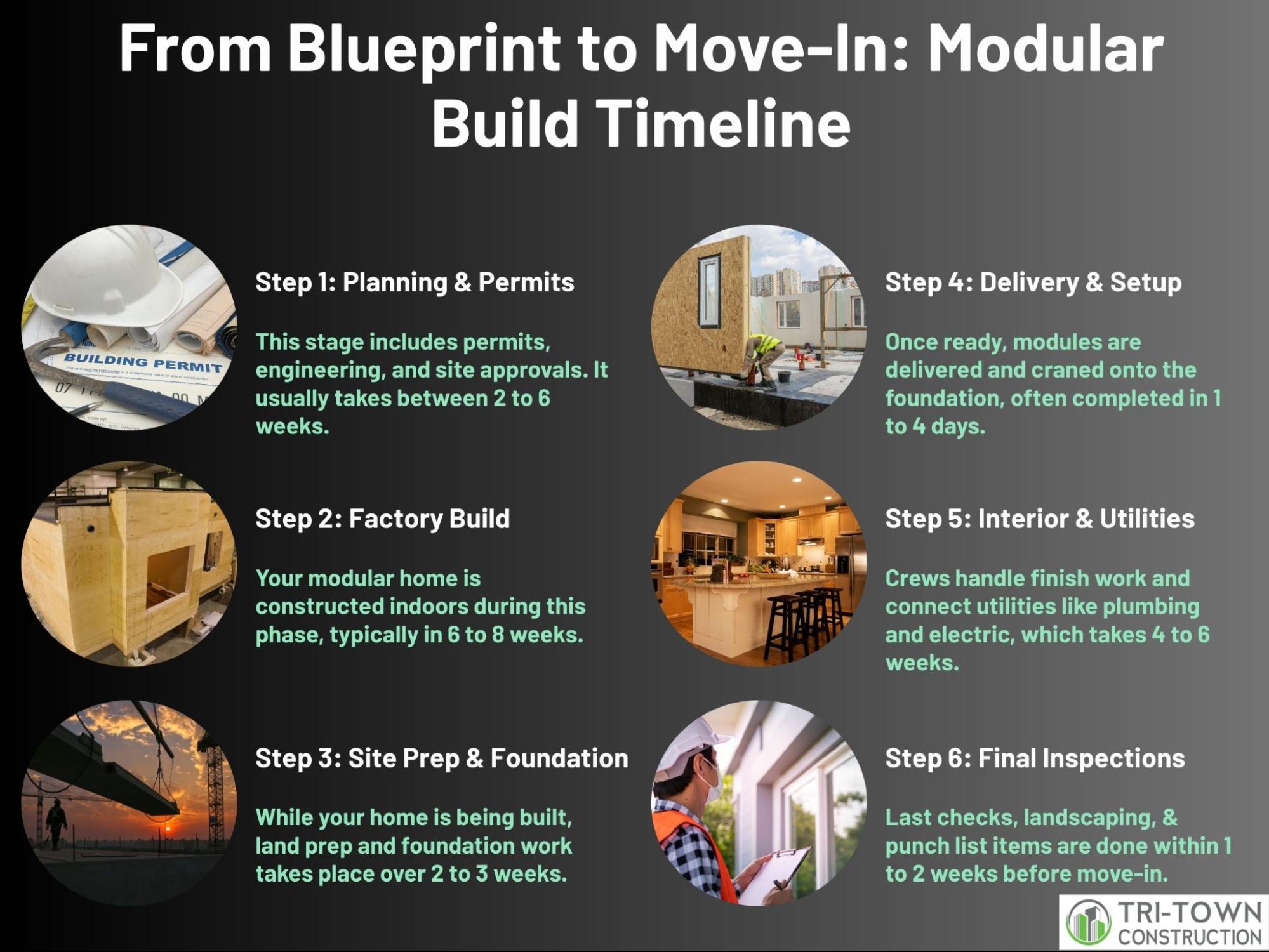

Here’s a quick look at how that timeline breaks down:

- Planning & permits: 2–6 weeks

- Factory build: 6–8 weeks

- Site prep & foundation: 2–3 weeks

- Delivery & setup: 1–4 days

- Interior finishing & utility hookups: 4–6 weeks

- Final inspections & move-in prep: 1–2 weeks

External delays like permits, weather, or utility hookups can add 2–3 months without good planning.

But with early decisions and smart scheduling, modular homes stay on track far better than traditional builds. That’s what makes them a fast, flexible option for today’s homeowners.

Want to see where delays happen, how to avoid them, and what makes a modular home storm-ready? Keep reading for everything you need to know before you build.

Why Modular Homes Are Faster to Build Than Traditional Homes

Building a Modular Home from Scratch in 2024: Full Start to Finish Process

A modular home is built in sections, or “modules,” inside a factory. These modules are then delivered to your land and assembled on a permanent foundation.

Unlike manufactured homes, modular homes meet the same building codes as site-built homes and can be fully customized.

1. Factory Building Saves Time

Since construction happens indoors, your build isn’t delayed by bad weather, material damage, or labor shortages.

Factory settings also allow for tighter quality control, better insulation, and more precise assembly.

2. Work Happens at the Same Time

One of the biggest time-savers is that factory construction and site prep happen at once. While your home is being built off-site, crews can install your foundation. This overlapping process shortens the overall build time by weeks.

3. Custom Doesn’t Mean Slow

Modular homes aren’t cookie-cutter. You can still choose your layout, finishes, and even outdoor features like lanais or decks.

Some people worry modular homes might look cheap, but with the right details, they look just like any custom home built from the ground up.

Now that you know why modular homes are built faster, let’s walk through the actual timeline, step by step, from your first permit to moving day.

Helpful Resource → Modular Homes Price Range: What You’ll Really Pay

From Blueprint to Move-In: How Long Does a Modular Home Really Take to Build?

Once you’ve decided to build a modular home, the next big question is: how long will it take?

While every project is a little different, most modular homes are completed in 4 to 6 months from the start of planning to move-in day. Here’s what the timeline typically looks like.

Step 1: Planning and Permits (2–6 weeks)

The first stage includes engineering, design approvals, permits, and site evaluations.

If you’re in a high-demand area or building in a flood zone, approvals can take longer, so it’s a good idea to start this process early, even while you’re still finalizing financing.

Step 2: Building the Home at the Factory (6–8 weeks)

While your permits are being processed, the home itself is built off-site in a factory.

Since the modules are assembled indoors, weather delays aren’t a concern. Factory teams work efficiently with streamlined production lines, which keeps the build on schedule.

Step 3: Preparing the Land (2–3 weeks)

At the same time the factory is building your home, crews can clear your land, pour the foundation, and get everything ready for delivery.

This overlap is one of the biggest time-savers in modular construction.

Step 4: Delivery and Setup (1–4 days)

When the modules arrive, a crane sets them onto the foundation. This part moves quickly, as little as a single day if weather and access are good.

Step 5: Interior Finishing and Utilities (4–6 weeks)

After setup, finishing crews connect electrical, plumbing, and HVAC systems, install stairs and trim, and complete any cosmetic work.

It’s also during this time that water and power are hooked up, which can take anywhere from a few days to a couple of weeks depending on the utility providers and inspector availability.

Step 6: Final Checks and Move-In (1–2 weeks)

Before you can move in, final inspections and punch list items are completed. Landscaping, driveway work, and minor fixes are typically handled in this window.

Quick Note: These are average timelines based on smart planning and steady progress. In reality, delays can happen, especially from permitting backlogs or if decisions stall during the design phase.

View this post on Instagram

If several issues stack up, your timeline could extend by 2 to 3 months or more. Starting early, staying organized, and making clear decisions helps keep your build on track.

Now that you know what to expect from start to finish, let’s look at how delivery day works, and what to consider before choosing where to build.

Delivery Day & Location: What Can Speed Up, or Slow Down, Your Modular Build

Once your modular home is built and ready for delivery, the process can move fast, but only if your location is properly prepared.

The delivery and installation phase is often quick, but it depends heavily on site conditions, local logistics, and weather. Here’s what to expect and how to make sure nothing slows you down.

1. How Modular Homes Arrive

Modular homes are delivered in large sections by transport trucks. Once on-site, a crane lifts each module and carefully places it onto the foundation.

This part of the process usually takes between one and four days, depending on access and weather.

2. Your Site Has to Be Ready

Before the modules arrive, your site needs to be fully prepped. That means cleared land, a completed foundation, and a solid plan for crane placement and staging.

Road width, tree cover, soil stability, and slope all factor into whether the delivery can go smoothly.

3. Weather Can Push Delivery Back

Because cranes are involved, wind and rain can delay delivery, even if everything else is ready. Crews need calm, clear conditions to safely place the modules on the foundation.

That’s why it’s smart to leave some flexibility in your schedule around delivery week.

4. Some Locations Add Extra Steps

If you’re building in a remote area or near the coast, extra time may be needed. Coastal lots often require more detailed engineering, flood zone elevation checks, and additional zoning approvals.

These aren’t deal-breakers, but they do require more planning upfront.

5. Know Local Rules Before You Build

Zoning restrictions, floodplain regulations, and access requirements vary widely by county. It’s important to understand these early, especially if you’re building in high-risk or high-demand areas.

Some of these rules can affect your foundation design or dictate the elevation of your home.

View this post on Instagram

With your site ready and delivery complete, the final phase begins: finishing the interior, connecting utilities, and clearing inspection.

But even the best-laid plans can hit snags, next, we’ll explore common delays and how to stay ahead of them.

What Can Delay a Modular Home Build, And How to Keep Things Moving

Modular construction is fast, but it’s not immune to delays. Most slowdowns don’t happen in the factory, they happen around it.

Here are the common trouble spots and how to stay ahead of them.

- Permits can slow everything down. Permit offices, especially in coastal or storm-prone counties, can get backed up for weeks. Start the process early, even before your financing is finalized, to avoid losing time.

- Utility hookups aren’t always quick. Getting power and water connected depends on your local providers and inspectors. Some areas take just days, others several weeks. Plan for possible wait time after your home is set.

- Foundation crews book out fast. Local demand can lead to long wait times for slab or pier installations. Booking early is key to keeping your schedule tight.

- Weather can pause delivery. If winds are high or the ground’s too soft, crane crews may delay setting your modules for safety. It’s wise to build in some flexibility during delivery week.

- Factories have busy seasons too. After storms or during peak months, factory schedules can fill up quickly. Choosing simpler floor plans or building in the off-season can help you secure a faster production slot.

Staying on track with a modular home is all about planning ahead, keeping communication open, and making smart timing decisions.

Helpful Resource → Can You Add On to a Modular Home? What to Know First

Bringing It All Together: Smart Planning Leads to Faster Move-In

View this post on Instagram

Building a modular home is one of the most efficient ways to get into a new home, especially in Florida, where time, weather, and local codes can create challenges for traditional construction.

By understanding the process, staying proactive, and choosing the right build partner, you can move from planning to move-in in as little as four to six months.

Every project has its own curveballs, but with solid planning and clear communication, you’ll be ready for them.

The key is knowing what to expect and staying one step ahead from day one.

Looking for a modular builder that delivers on schedule and meets Florida’s strict code requirements?

Tri-Town Construction builds code-compliant modular homes with speed, precision, and coastal durability, built for your timeline and your future.