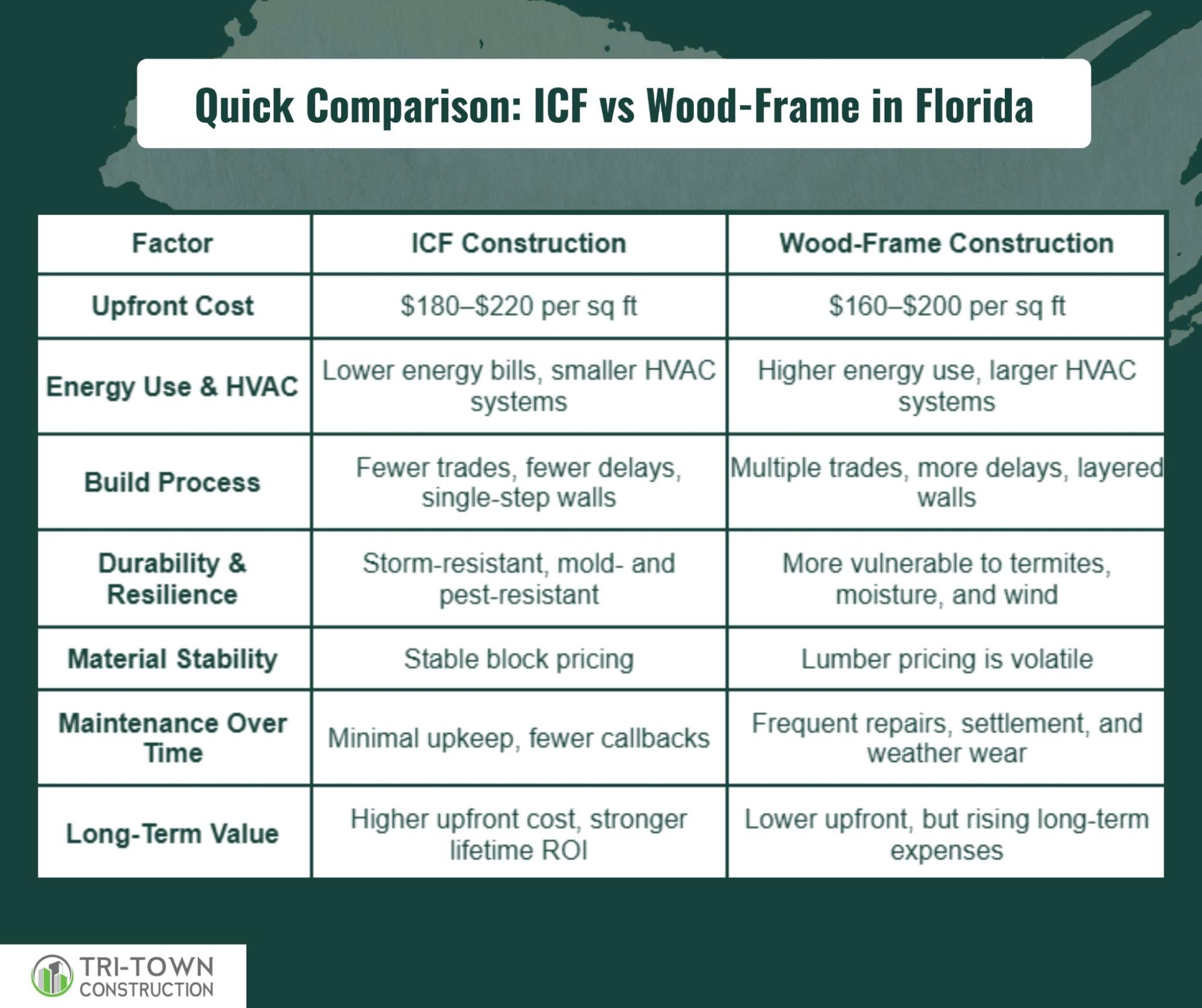

In Florida, ICF homes cost around $180–$220 per sq ft, while wood-frame homes run $160–$200. But ICF offers lower energy bills, fewer repairs, and more storm resistance, making it a stronger long-term value despite a higher upfront price.

Build Smarter From the Ground Up: What You Need to Know Right Now

Florida homeowners should look beyond just the upfront price. Wood-frame homes may seem cheaper, but often lead to higher energy bills, moisture damage, and more repairs.

ICF homes cost more to build, but they’re stronger, better insulated, and easier to maintain over time. Quick facts to help you compare:

- ICF cost: $180–$220/sq ft (lower utilities, fewer repairs)

- Wood-frame cost: $160–$200/sq ft (higher upkeep over time)

- Utility savings with ICF: ~$1,500/year on a 2,500 sq ft home

- ICF benefits: Better insulation, storm resistance, quieter interiors

- Wood-frame risks: Termites, mold, weather delays, repair callbacks

ICF isn’t always the obvious choice up front, but for many, it’s the one that holds up best year after year.

And if you’re weighing both systems, there’s one hybrid approach gaining ground for all the right reasons…

What’s the Real Price to Build with ICF vs Wood-Frame Today?

Before choosing how to build your next home, it’s important to understand what you’re really paying for.

Here’s a side-by-side look at ICF and wood-frame construction costs in Florida, both upfront and over the long run.

What is ICF (Insulated Concrete Forms)?

ICF, or Insulated Concrete Forms, are hollow blocks made of expanded polystyrene (EPS) foam. These blocks are stacked like Lego, reinforced with steel rebar, and then filled with concrete.

The result is a solid, insulated concrete wall system that serves as structure, insulation, and air barrier in one.

Average Cost: In Florida, building with ICF typically ranges from $180 to $220 per square foot, depending on design complexity, finish level, and site conditions.

What is Wood-Frame Construction?

Wood-frame construction uses dimensional lumber to build the home’s skeleton.

Layers of batt insulation, vapor barriers, sheathing, and cladding are then added to complete the envelope.

This system is widespread across the U.S. and relies on multiple trades and sequential construction steps.

Average Cost: A typical wood-frame home in Florida ranges from $160 to $200 per square foot, depending on the quality of materials and build approach.

A Long-Term Cost Perspective Worth Considering

It’s easy to focus on the upfront cost of building, but monthly and yearly expenses often tell a bigger story. Energy use, in particular, can make a noticeable difference over time.

ICF homes usually cost about $0.03 per square foot per month to power, while wood-frame homes average around $0.10 per square foot.

For a 2,500 square foot home, that adds up to about $1,500 each year, or $45,000 over 30 years.

Over time, these steady savings can make a real difference for homeowners who plan to stay in one place.

Related Resource → Wood-Frame Houses In Florida | Benefit, Risk & Comparison

What Drives the Price of an ICF Home Up or Down?

The cost of building with ICF depends on more than just square footage. Materials, labor, site conditions, and finish choices all play a role in shaping the final number.

1. Wall Thickness, Rebar, and Block Quality

Foam thickness, core width, and rebar spacing affect both strength and insulation. Higher-performance walls cost more but offer better efficiency and durability.

The brand of block also matters, as some offer tighter interlocks and higher R-values.

Expected Cost: Standard builds range from $180–$195 per sq ft, while thicker walls or premium blocks can raise costs to $210–$225 per sq ft.

2. Site Conditions and Climate Zone Requirements

Lots in flood zones or coastal terrain often need elevation, drainage, and reinforced footings. These site-specific demands add to the complexity and cost of ICF builds in regions like Southwest Florida.

Expected Cost: Projects in high-risk flood zones may see costs rise by $10–$15 per sq ft for elevation and foundation work.

3. Labor and Workflow Simplicity

ICF replaces multiple layers, framing, insulation, sheathing, with one streamlined system. Fewer trades are needed, which simplifies scheduling. But specialized crews are essential for proper installation.

Expected Cost: Skilled ICF labor adds $8–$12 per sq ft, though fewer overall trades can help balance the budget.

4. Exterior and Interior Finishes

Cladding choices like stucco, siding, or fiber cement affect prep time and cost. On the inside, drywall may require furring strips based on code and layout needs.

Expected Cost: Add $6–$15 per sq ft depending on the chosen finishes.

5. Permitting, Energy Code, and HVAC Sizing

ICF often exceeds Florida’s energy and storm codes, which helps reduce permitting delays. Its energy efficiency also allows for smaller HVAC systems, cutting mechanical costs.

Expected Cost:

- Permitting costs range from $8,000–$15,000

- HVAC system savings range from $3,000–$6,000

6. Design Choices and Build Strategy

Some homeowners use ICF only for lower levels or safe rooms, but many later wish they went full height. Full-wall ICF brings more long-term comfort and efficiency.

Expected Cost: Using ICF for foundations only can reduce ICF-related costs by 30–40%, but it limits system performance.

7. Market Stability and Budget Predictability

Unlike lumber, ICF block pricing stays relatively stable, even during market swings. That consistency makes budgeting more predictable in active construction markets like Florida.

Expected Cost: ICF pricing typically fluctuates within a 10–12% range, compared to more volatile lumber costs.

While ICF offers a more streamlined and resilient approach, its cost depends heavily on design choices, site demands, and material selections.

To understand the full picture, it’s worth looking at how wood-frame homes stack up when all the hidden costs come into play.

Related Resource → ICF Home Lifespan: Why These Homes Last So Long

What Affects the Cost of Wood-Frame Homes

Wood-frame construction often looks more affordable at first.

But once you dig into the layers, labor needs, and Florida’s tough climate, hidden costs begin to show up quickly.

1. Wood Type and Quality Variation

Framing quality depends on the type of wood used. SPF and Hem-Fir are common, but engineered or modular-grade lumber improves durability and reduces waste at a higher material cost.

Expected Cost: High-grade or engineered wood can add $5–$10 per sq ft, depending on supplier availability and demand.

2. Trades, Workflow, and Weather Risks

Wood framing requires separate crews for framing, insulation, and air sealing. Add to that delays from rain or humidity, and labor schedules can stretch fast in coastal Florida.

Expected Cost: Labor coordination can add $10–$18 per sq ft. Weather delays may cost an extra $3,000–$7,000 and extend timelines by 1–3 weeks.

3. Wall Assembly Layers Add Up

Unlike ICF, wood-framed walls need layered barriers and insulation to meet code. These extra materials and steps increase both labor and install complexity.

Expected Cost: Combined wall assembly can total $25–$35 per linear foot, depending on system design.

4. Long-Term Maintenance Needs

Wood structures in Florida face mold, termite, and moisture risks. These can result in frequent repairs, especially if protection systems aren’t regularly maintained.

Expected Cost: Termite treatment and moisture repair costs range from $300–$1,200 per year, depending on exposure and upkeep.

5. Callbacks and Settlement Issues

Wood homes may shift, crack, or develop insulation gaps, especially in coastal zones. These often lead to post-build repairs and added warranty costs for builders.

Expected Cost: Builder warranty expenses may rise by 15–25% over ICF due to long-term repair frequency.

6. Site-Built vs Modular Framing

Site-built homes can suffer from uneven craftsmanship. Modular wood framing offers better consistency and material efficiency under factory-controlled conditions.

Expected Cost: Modular-grade framing reduces waste by 10–15% and improves labor efficiency by 20% or more.

7. Regional Pricing and Hybrid Options

In regions like Southwest Florida, high demand and labor shortages reduce wood’s cost advantage. Some builders now pair modular interiors with ICF shells for durability and speed.

Expected Cost:

- Wood-frame homes in Florida typically range from $160 to $200 per sq ft

- Hybrid modular-ICF systems cost slightly more up front but lower long-term risks

Even with its lower starting price, wood-frame construction carries several hidden costs that can add up over time.

To get a full picture of total cost, it’s just as important to look at what stays the same in every build.

Related Resource → Wood vs Concrete Block in Florida: Which Is Better?

These Costs Stay the Same Whether You Choose ICF or Wood

No matter which building method you choose, some construction costs won’t change.

These are the fixed parts of a project that apply to nearly every home in Florida, regardless of whether the walls are concrete or wood.

- Land acquisition is the first constant, the price of the lot stays the same whether you build with ICF or wood.

- Site clearing, excavation, and grading are standard prep tasks based on land condition, not wall material.

- Permits and impact fees depend on square footage and municipal rules, not the type of construction.

- Utility hook-ups like water, sewer/septic, and electric are required for all builds, regardless of structure type.

- Driveways, irrigation, and landscaping are shaped by design and lot layout, not construction method.

- Interior fixtures such as appliances, cabinets, and flooring are part of the finishing phase and don’t depend on wall system.

- Roofing costs stay similar unless tied directly to a specialty wall system, materials like asphalt or tile remain consistent.

These shared costs are important to factor in when comparing total budgets side by side.

On average, these fixed costs can add up to $100–$130 per square foot, depending on location, finishes, and site conditions.

Once you account for the fixed costs every home shares, the real difference comes down to how you build the structure itself.

For some homeowners, the smartest option is combining the strengths of both systems.

A Smarter Way to Build: Modular + ICF Combined

View this post on Instagram

For homeowners looking for durability and efficiency, combining modular construction with an ICF shell is a long-term strategy worth considering.

Modular interiors are built off-site, which speeds up timelines and improves quality control. These units arrive nearly finished, reducing delays and labor costs.

When paired with ICF exterior walls, you get the storm resistance, energy savings, and sound insulation that wood alone can’t match, especially important in Florida’s climate.

Tri-Town Construction has used this hybrid approach to deliver faster builds without compromising on strength. While it may cost slightly more upfront, it often saves time and maintenance in the long run.

For those who want the speed of modular with the staying power of concrete, this blend offers a solid middle ground.

Final Take: Weighing Costs with the Long View in Mind

Choosing between ICF and wood-frame construction isn’t just about upfront costs, it’s about how your home performs over decades.

Florida’s climate, code requirements, and insurance landscape make resilience and energy efficiency more than just nice-to-haves.

ICF delivers long-term value, while modular approaches add speed and consistency. The real win? A thoughtful mix of both.

If you’re planning to build in Southwest Florida, Tri-Town Construction offers fully code-compliant ICF homes and modular-ICF hybrid builds designed for today’s challenges.

Reach out to learn how we build stronger, smarter, and more storm-ready homes that stand the test of time.