Modular homes are built in factory sections and assembled on-site in days, not months. They offer speed, durability, and custom design while meeting the same building codes as traditional homes.

Why Modular Homes Are a Smarter Way to Build in Florida

Modular homes are built in factory sections and set on-site in a day, offering a faster, cleaner, and more precise path to a strong, code-compliant custom home.

Here’s what makes modular homes stand out:

- Factory-built in controlled conditions for better quality and tighter insulation

- Faster timelines with fewer weather delays or subcontractor issues

- Customizable floor plans and finishes, including multi-story options

- Stronger framing to handle transport and storms

- Can be built on concrete slabs, crawlspaces, or pilings for flood zones

- Easy to prep for solar panels, battery storage, or expansion

- Comparable financing and resale value to traditional homes

Modular building isn’t just a shortcut; it’s a smarter strategy for homeowners who want more control, fewer delays, and peace of mind in storm-prone areas.

And if you’re serious about building in Florida, especially post-hurricane, there are key steps and details you won’t want to miss.

What Modular Homes Are and Why They’re a Good Investment

Modular homes are built in sections at a factory and assembled on-site, permanently installed on a traditional foundation.

They aren’t mobile homes or trailers, they follow the same building codes as any site-built house and are treated as real property.

1. Not a Trailer, Not a Kit Home

One common misconception is that modular means low-quality or limited design. The truth? Modular homes can be fully custom.

You can have vaulted ceilings, open-concept layouts, two-story floor plans, and high-end finishes, just like any luxury build.

2. Stronger by Design

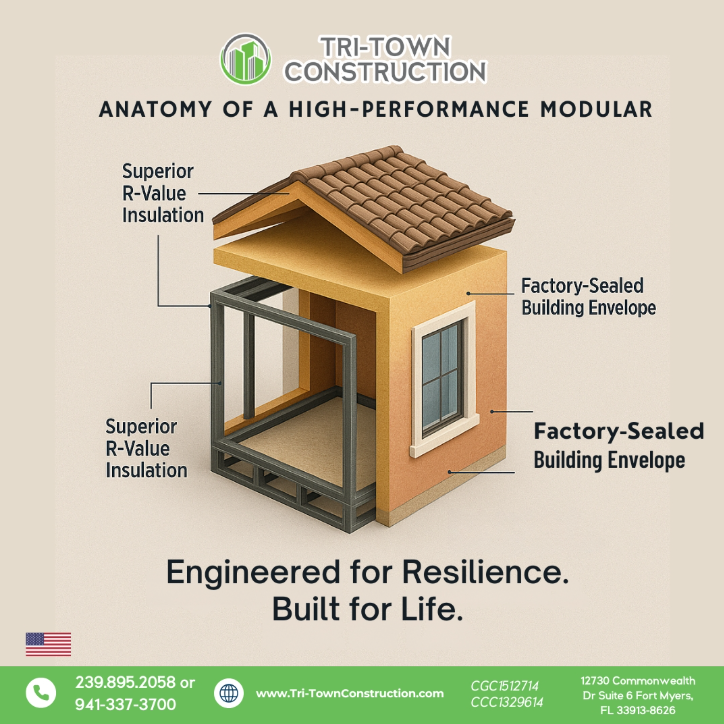

Because each section has to withstand transport and crane lifting, modular homes are engineered with extra structural support.

Built indoors, they avoid weather damage and benefit from tight quality control, precision tools, and drier materials. That adds up to better insulation and durability.

3. Financing and Resale Are Straightforward

Banks treat modular homes just like traditional ones. You can use a VA, FHA, or conventional mortgage.

And when built right, modular homes maintain resale value, especially in high-demand areas like Southwest Florida.

4. Custom Without the Chaos

You still get to design your dream home, but without the hassle of on-site weather delays or disorganized crews.

Most finishes, plumbing, and wiring are handled in the factory, which speeds up the timeline and reduces risk.

5. Built for Florida Living

Modular homes can be designed to meet strict Florida storm codes, with hurricane straps, wind-resistant roofing, and quick construction timelines that help you get dried-in before storm season hits.

Now that we’ve cleared up what modular homes are, and what they’re not, let’s walk through how the full assembly process actually works.

Helpful Resource → Florida Modular Homes Guide: Cost, Build, Safety & More

The Modular Home Assembly Process from Start to Finish

Once a modular home is designed and approved, the real magic begins.

Unlike traditional construction that unfolds slowly on-site, modular building happens in two parallel tracks, one at the factory and one at the build site, resulting in a streamlined, efficient process from design to move-in.

Step 1: Designing Your Home

The process starts with selecting or customizing a floor plan.

Whether it’s a single-story layout or a multi-module, two-story design, the goal is to finalize structural details, finishes, and fixtures upfront.

Designs are engineered to meet local building codes and wind zone requirements, especially important in coastal or hurricane-prone areas.

Once plans are approved, production and site work begin at the same time.

Step 2: Factory Construction Begins

Inside a controlled factory setting, modules are constructed with precision. Walls, floors, and roof panels are built simultaneously.

During this time, major systems, electrical wiring, plumbing lines, HVAC ducts, are installed within the walls and ceilings of each module.

Because it all happens indoors, delays from rain, humidity, or extreme temperatures are completely avoided.

Modules are often built using more framing material than traditional homes to ensure durability during transport and assembly.

Inspections happen throughout the build, often exceeding on-site code requirements.

Step 3: Modules Are Prepped and Shipped

Once complete, each module is wrapped in protective materials to shield it from moisture and debris. Modules are loaded onto flatbed trailers and transported to the site.

Depending on the size of the home, this may involve multiple shipments.

Transportation must be carefully planned, especially for homes with wide or oversized modules or those headed to tight or remote lots.

Step 4: Site Prep and Foundation

While the home is being built in the factory, crews on-site are preparing the foundation.

Most modular homes are installed on permanent concrete foundations, but in flood-prone regions, pilings or elevated platforms may be used.

Once the foundation is ready, the site is cleared and staged for crane operations.

Step 5: Set Day

Set day is one of the most impressive stages of the modular process.

A crane arrives early in the morning, and modules are carefully lifted from the trailers and lowered into place on the foundation.

Crews use hand signals to communicate with the crane operator, ensuring precise placement.

In just a few hours, modules are aligned, leveled, and locked into position. A good crew can complete the structural assembly of a home in less than a day.

Step 6: Joining and Weatherproofing

Once the modules are in place, seams between each section are sealed and reinforced.

Roof panels are raised, gable ends are installed, and knee walls are set to complete the structure. These steps ensure the home is “dried-in,” meaning fully enclosed and protected from weather.

Decorative features like porches, dormers, and trim may be added during this stage, giving the home its final architectural character.

Step 7: On-Site Finishing Work

Even though most of the build is done in the factory, about 15 to 25 percent of the work still happens on-site.

This includes completing the roofing, siding, interior painting, flooring, staircases, railings, and utility hookups.

Depending on the complexity of the design, this stage may last several weeks.

Step 8: Permitting and Final Inspection

Once assembly and finishing are complete, local building officials inspect the home to ensure everything meets code.

While permitting timelines can vary, especially in post-storm regions, having a well-prepared crew and clear documentation helps avoid unnecessary delays.

View this post on Instagram

With the structure now fully assembled and inspected, the focus shifts to why modular homes offer more than just speed, they often outperform traditional homes in resilience, efficiency, and value.

Let’s explore why modular might be the smartest way to build today.

Helpful Resource → How Long Does It Take to Build a Modular Home in Florida?

Why Modular Homes Are a Smart Decision

Modular construction offers more than just convenience, it’s a smarter, more resilient way to build, especially when time, budget, and long-term performance matter.

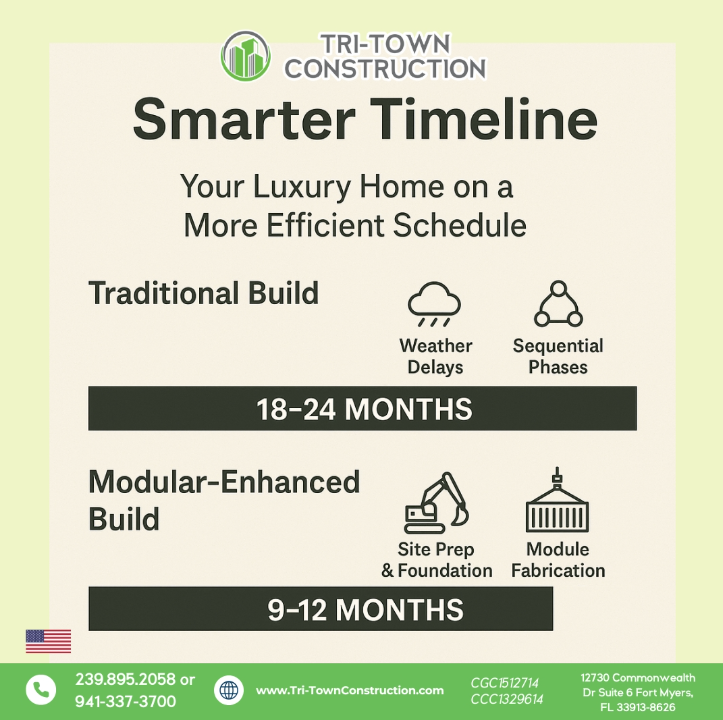

1. Faster Timelines Without Cutting Corners

Because the foundation and modules are built simultaneously, modular homes shave weeks or even months off the construction schedule.

Once delivered, a home can be fully dried-in within a single day, reducing the risk of weather damage and accelerating move-in timelines.

2. Less Disruption, More Control

Compared to traditional construction, modular homes create less noise, mess, and traffic in your neighborhood.

Most of the heavy lifting happens off-site, meaning fewer disruptions to your daily life during the build.

3. Built for Efficiency

Factory precision means tighter seams, better insulation, and reduced material waste. That results in lower utility bills, better indoor comfort, and a smaller environmental footprint.

4. Budget-Friendly by Design

One of the biggest advantages is cost predictability.

Because most of the work is done in a controlled environment, pricing is more accurate and delays are minimized.

That said, it’s important to plan ahead for items like land prep, driveways, and landscaping, which are often separate from the base home price.

5. Ready for the Real World

Modular homes are engineered to survive transport, and that strength translates to resilience on-site, particularly in storm-prone regions.

They’re also easy to expand, making it simple to build in phases if needed.

Choosing modular isn’t just about building faster. It’s about building smarter, safer, and more sustainably, with flexibility to grow over time.

Also Read → Can You Add On to a Modular Home? What to Know First

Things You Should Know Before You Build Modular

While modular homes offer clear advantages, the success of your project still depends on good planning and the right team.

Here are a few key things every homeowner should know before building modular.

1. Site Access and Preparation Matter

Before modules arrive, your lot needs to be ready, not just the foundation, but the space around it. Flatbeds, cranes, and crew vehicles all need access.

Tight roads, overgrown trees, or sloped lots can complicate delivery and setup. A good builder will assess these logistics early to avoid surprises on set day.

2. Understand Local Permitting Timelines

Permitting is always part of the process, and in Florida, it can take time, especially in areas still recovering from hurricanes.

Be prepared for delays in counties with high demand or limited staffing. The more experienced your contractor is with local agencies, the smoother things tend to go.

3. Not Every Builder is Modular-Savvy

Modular home assembly requires precision and coordination.

From setting modules to managing inspections, not every general contractor is equipped for it. Working with one who understands modular timelines, equipment needs, and finishing standards is essential.

4. Know What Your Warranty Covers

Most modular builds are split into two warranties, one for factory-built components and another for on-site work.

Be clear on who’s responsible for what, and make sure it’s in writing.

Before breaking ground, the right prep and partners make all the difference.

The Bottom Line on Building Modular

Modular homes are redefining what it means to build smart.

From faster timelines and factory precision to storm-rated strength and true design flexibility, they offer a practical and future-ready path to homeownership.

Whether you’re rebuilding, downsizing, or starting fresh, modular homes offer the quality and flexibility you need, without the stress of traditional construction.

Understanding the full process, from design to delivery, helps you make confident decisions and avoid common pitfalls.

With the right planning and team behind you, a modular home can be one of the best investments you’ll ever make.

Looking to build modular in Southwest Florida?

Tri-Town Construction specializes in custom modular homes built to withstand storms, timelines, and expectations.

Let’s bring your vision to life, with strength, care, and integrity.