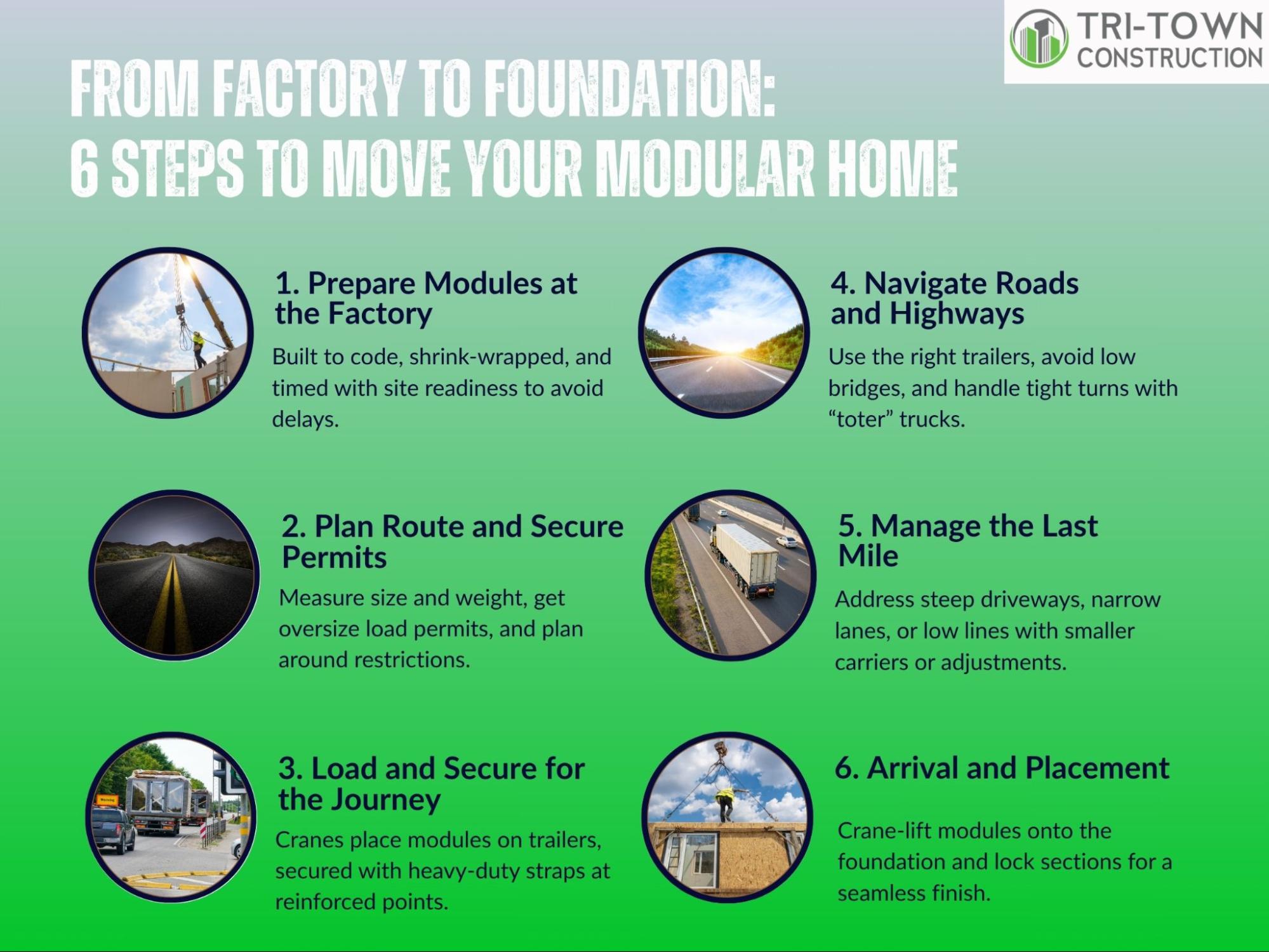

Safe and Efficient Transport of Modular Homes Explained

Modular homes are transported in factory-built sections, secured on specialized trailers, escorted under oversize load permits, and delivered to the build site, where cranes place them on a prepared foundation for final assembly.

How Modular Homes Travel Safely from Factory Floor to Finished Foundation

Transporting a modular home requires precise construction and careful logistics.

With each section wrapped, loaded on specialized trailers, and delivered by skilled crews, the process ensures safe arrival to the location. Key points in the process:

- Factory preparation: Modules are inspected, shrink-wrapped, and weatherproofed.

- Route planning: Permits, escorts, and clearance checks are arranged.

- Loading: Cranes place modules onto trailers, secured with heavy-duty straps.

- Transport: Drivers follow planned routes to avoid low bridges or tight turns.

- Last-mile access: Smaller trucks, lifts, or road prep for tricky sites.

- Placement: Cranes align and secure modules on the foundation.

Weeks of preparation and planning ensure smooth delivery.

Knowing each step helps you avoid delays, prevent damage, and sidestep the most common and costly pitfalls in modular home transport.

From Factory to Foundation: The Step-by-Step Moving Process

Transporting a modular home is a coordinated process that blends engineering, logistics, and skilled labor.

Every stage plays a role in protecting the structure and keeping the project on track from the factory floor to the build site.

1. Preparing Modules at the Factory

Before the journey begins, modules are built and protected for the road ahead. Care here saves time and prevents damage later.

- Constructed to local building codes for structural integrity

- Shrink-wrapped for weather resistance, with added protection for coastal hauls

- Delivery timing coordinated with site readiness

A carefully prepared module leaves the factory in prime condition, ready to withstand transit and avoid the delays of off-site storage.

This foundation of preparation sets the stage for a smooth move.

2. Planning the Route and Securing Permits

Safe delivery depends on choosing the right route and meeting all legal requirements. Every detail is reviewed before departure.

- Measure and confirm height, width, and weight

- Obtain oversize load permits and arrange escorts if needed

- Plan around bridge clearances, lane widths, and travel hour rules

Thorough planning reduces risk, prevents last-minute rerouting, and keeps the project compliant. By addressing these factors early, the transport team sets the tone for an efficient trip.

3. Loading and Securing for the Journey

Modules must be lifted and fastened in ways that protect them from start to finish. Precision here avoids damage on the road.

- Cranes position modules on flatbeds, step-decks, or extendable trailers

- Heavy-duty straps or chains secure them at reinforced points

- Tie-down techniques prevent movement over rough surfaces

Secure, balanced loading ensures the home arrives exactly as it left the factory. This care allows the journey to proceed with confidence.

4. Navigating Roads and Highways

Once underway, drivers must guide large loads safely over varied terrain. The right equipment and route make all the difference.

- Select trailer types matched to size, weight, and terrain

- Use “toter” trucks with flexible hitches for tighter turns

- Avoid routes with low bridges or strict weight limits

Skilled driving keeps modules safe until they near their destination. With the bulk of the journey complete, the focus turns to the most challenging stretch.

5. Managing the Last Mile

The final approach often tests the planning done earlier. Tight spaces and site-specific obstacles must be handled with care.

- Maneuver through steep driveways, sharp bends, or narrow lanes

- Arrange branch trimming or power line adjustments in advance

- Use smaller carriers or special tools for limited access

By anticipating these hurdles, crews avoid costly delays and protect the modules. This stage ensures the delivery ends as smoothly as it began.

6. Arrival and Placement on Site

Setting the modules on their foundation marks the transition from transport to construction. Accuracy is crucial here.

- Inspect and confirm the foundation is level and secure

- Use cranes to place modules with precise alignment

- Lock sections together for a seamless finish

Once placement is complete, the build moves to final assembly. This moment is the payoff for every mile and every careful step taken along the way.

A well-executed transport plan gets your home from factory floor to foundation without compromise.

The next question is how far it can realistically travel, and how distance impacts both the logistics and the final cost.

Helpful Resource → Can a Modular Home Survive a Hurricane?

When Distance Matters: Can You Ship Across the Country?

The location of your modular home’s manufacturer can have a major impact on delivery logistics.

While moving modules across the country is possible, the distance involved changes both the complexity and the cost of the journey.

1. Buying From Any State

You can purchase a modular home from anywhere in the United States and have it delivered to your property.

However, each state along the delivery route has its own rules for oversize loads, including permits, escort vehicle requirements, and restrictions on travel times or days.

This makes planning more complex the further the modules must travel.

2. Extra Costs and Logistical Challenges

Long-distance moves involve higher transportation costs due to fuel, driver time, and specialized equipment.

Seasonal weather can cause delays, and each new state line can mean reapplying for permits. The more miles involved, the greater the risk of disruptions to the delivery schedule.

3. Why Regional Sourcing Is Often Smarter

Choosing a regional manufacturer can cut down on travel time, reduce the number of permits needed, and lower overall costs.

It also minimizes the time modules spend in transit, reducing exposure to potential damage. While cross-country deliveries are possible, shorter hauls typically offer smoother, more cost-effective results.

Whether your home travels 50 miles or 2,000, distance directly affects the budget.

Understanding how far you want to ship your home is the first step in estimating costs, which is exactly what we will cover next.

Helpful Resource → Modular Homes Pricing in Florida | Accurate Build Cost

The Cost of Moving a Modular Home

View this post on Instagram

Understanding the costs involved in transporting a modular home helps set realistic expectations for your project.

From standard fees to hidden expenses, each factor plays a role in the final price tag.

Base Transport Fees and Per-Mile Charges

Most transport companies charge a base fee that covers standard preparation, loading, and delivery. This can range from $3,000 to $10,000 depending on the size and number of modules.

On top of that, per-mile rates are typically $5 to $15 per mile, with the higher end applying to oversize or heavy loads.

Larger or heavier modules may require specialized trailers, which can increase the rate further.

Escort Costs and Special Equipment Surcharges

Oversize loads often require escort or pilot vehicles, especially for long or multi-state deliveries.

These typically cost $1.50 to $2.50 per mile per escort vehicle. Crane services for lifting modules onto the foundation can range from $500 to $1,500 per day.

Additional charges may apply for “toter” trucks in tight spaces or ground protection mats, which can add several hundred dollars to the bill.

Hidden Costs That Can Add Up

Unexpected road closures, bad weather delays, or last-minute changes to the route can require extra crew hours, billed at $100 to $200 per hour.

Rescheduling fees, new permit applications, and additional storage costs can also push the budget higher. In some cases, these extras can add 10–20% to the original estimate.

In-State vs. Cross-Country Moves

Shorter, in-state moves are generally less expensive and involve fewer logistical hurdles.

These often fall in the $5,000 to $15,000 range.

Cross-country hauls can exceed $20,000 to $30,000 once mileage, permits, escorts, and driver availability are factored in. For oversized or multi-section homes, costs can climb even higher.

Knowing these cost factors allows you to plan your budget more accurately and avoid surprises along the way.

Understanding the full range of transport costs is only part of the equation.

The next challenge is ensuring your home can actually reach its destination, even when the route or site presents serious space and access limitations.

Helpful Resource → Modular Homes Price Range: What You’ll Really Pay

Beyond The Price Tag: Tricky Spaces and Tight Lots

Knowing the cost is important, but physical delivery challenges can be just as critical.

- Tight Access: Narrow streets or sharp turns can require alternate routes or smaller vehicles.

- Steep Approaches: Inclined driveways or hills may need specialized towing or grading work.

- Urban Constraints: Dense neighborhoods can demand crane lifts from nearby streets.

- Oversized Sections: Large modules might need splitting into smaller sections for safe entry.

- On-Site Adjustments: Branch trimming, utility line moves, or temporary fence removal may be necessary.

Addressing these potential obstacles early ensures your modular home not only fits your budget but also reaches its destination smoothly and without costly delays.

Preparing for site constraints is only half the battle, the road itself can present risks that demand just as much attention and planning.

Potential Risks on the Road, and Who Covers Them

View this post on Instagram

Transporting a modular home takes more than loading and driving, anticipating risks ensures smoother, safer delivery.

Potential Risks on the Road:

- Load Shifting: Sudden stops or sharp turns can cause slight frame adjustments or joint stress.

- Siding Damage: Tight maneuvers or flying debris may scratch or dent exterior panels.

- Roofing Wear: High winds can lift or tear roofing materials if not properly secured.

- Alignment Issues: Continuous vibrations may cause doors or windows to shift out of place.

- Weather Exposure: Damaged wrapping can allow rain, dust, or salt air to reach the structure.

- Access Delays: Low wires, tree branches, or narrow approaches can hold up delivery unexpectedly.

Recommended Insurance Protections

Homeowners should confirm the hauler’s insurance coverage and limits before transport. Adding a temporary builder’s risk or transit insurance policy can provide extra protection, especially for long-distance or high-value moves. These policies can cover both physical damage and certain delays.

Understanding these responsibilities ensures that, if something happens on the road, you know exactly how to address it.

Next, we’ll explore how to navigate challenges during delivery, from weather delays to site access issues, and keep the project on track.

Challenges That Can Derail Delivery, and How to Avoid Them

Even the best-planned modular home deliveries can run into unexpected problems. Knowing the most common challenges allows you to prepare for them before the trucks even leave the factory.

Challenges That Can Derail Delivery:

- Severe Weather: High winds, heavy rain, or storms can halt transport and crane operations.

- Permit Delays: Missing or incorrect permits can stop a delivery at a state or county line.

- Mechanical Failures: Truck or trailer breakdowns can cause costly rescheduling.

- Access Problems: Blocked roads, parked vehicles, or unprepared driveways can delay arrival.

- Utility Conflicts: Power lines or poles in crane paths can require last-minute adjustments.

- Site Conditions: Soft ground, flooding, or debris can prevent safe placement of modules.

How to Avoid Them

Avoid delays with solid contingency planning. Secure permits early and monitor weather forecasts.

Survey the site in advance and coordinate with utility companies. Keep crews in constant communication to resolve issues before they become costly.

Final Word: Partnering With Experts for a Smooth Move

Transporting a modular home is a complex process that demands precision, planning, and on-the-ground experience.

From securing permits to navigating the last mile, every stage affects the safety of your investment and the timeline of your project.

View this post on Instagram

Partnering with professionals who understand both the technical requirements and the unique challenges of your site can make the difference between a smooth delivery and a stressful one.

At Tri-Town Construction, we combine local knowledge with proven logistics expertise to ensure every modular home reaches its foundation in perfect condition.

Whether your site is tucked into a narrow neighborhood street or set along the coast, our team delivers with absolute care.

Contact us today to discuss your modular home project and learn how we can help bring it home, the right way.